Product impacts, risks, and opportunities

CARING FOR COPPER BEYOND ITS PRODUCTION

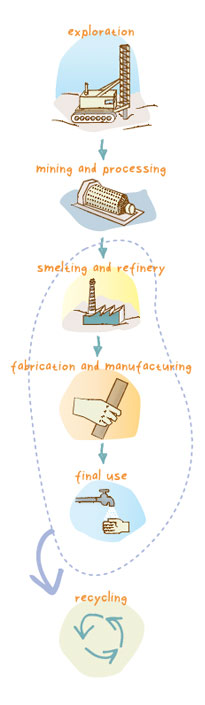

(MM11) Programs and progress relating to materials stewardship. At Codelco, the world’s greatest copper producer, we seek to continually identify, understand, and manage our impacts throughout our supply chain. This is why, either independently or as members of industry associations, we build and promote the development of research to learn all aspects associated with the uses of copper, while at the same time ensuring that this knowledge can be applied to the development of regulations on its use. Of special interest is the ongoing assessment of the ecological efficiency and sustainability of copper products in general, particularly through their key business processes and products’ value chain.

![]()

For Codelco, extended responsibility of

the copper producer or “copper stewardship”

means seeking to increase

the value of the metal and its uses in

society in a responsible, consistent, and

caring way a shared commitment with

our stakeholders in the production,

use, disposal and recycling ofcopper is

essential for a process that will benefit

companies, their employees, clients and

society in general.

![]()

(2.10)

Awards received in the reporting period.

Codelco’s Chief Executive Officer, Diego

Hernández, along with other representatives

of Fundación Chile and the Catholic

University of Valparaíso, received on

behalf of EcoSea the Avonni 2011 award

in the category of Industrial Innovation,

for the production of copper cages for

fish farming.

CARBON FOOTPRINT AND OTHER LIFE CYCLE INDICATORS

We have been working on calculating our products’ carbon footprint for several years, either in the context of their Life-Cycle Inventory or by using specific calculators for this indicator.

(PR1) Life cycle stages ni which health and safety impacts of products and services are assessed for improvement, and percentage of significant products and services categories subject to such assessment procedures. In 2011 we began the process of updating the Codelco Copper Life Cycle Inventory with operational data from 2010, and we hope to complete this inventory during 2012. In addition, we completed the second phase of the Cathode Global Life Cycle Inventory study carried out with the support of the International Copper Association (ICA), along with other industry actors. The objective of this study is to have a database on life cycle inventories of copper (cathodes) representing the technological and geographical diversity of the industry in the world, and its results will enable specialized authorities to both derive inventories of manufactured products and estimate materials sustainability indicators.

Knowledge and control of risks associated to products

(EN26) Initiatives to mitigate environmental impacts of products and services, and extent ofimpact mitigation. Following the trends on regulations for risk control of chemicals prevalent in the world’s most developed regions, during 2010 we completed the development of a program for labeling products based on their hazardousness and generating updated safety sheets in the language of every country of destination.

(PR3) Type of product and service information required by procedures, and percentage of significant products and services subject to such information requirements. (R) We are standardizing our labels and materials safety sheets for the Corporation’s main products in accordance with the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), of the United Nations. For European destinations, however, the safety sheets conform with the requirements of the new Guideline on Classification and Labelling of the European Union.

Codelco and the new trends in assessing risks and hazards of chemicals

The implementation of a single global classification system of substances based on their hazards (physical, chemical, environmental and to human health) as well as of tools for controlling the associated risks, has entailed significant challenges for the producers of chemical substances or mixtures (this includes metals and metal compounds).

During 2011 several regulatory scenarios have arisen, where the hazardousness status of metal concentrates has been discussed. In this context, as part of the copper industry, we have collaborated in the development of a classification system of copper concentrates using the criteria established by the GHS.

![]()

Copper Cathodes Global Life

Cycle Inventory

A life cycle inventory (LCI) of a material

is a methodology that allows quantitatively

estimating the natural resources

consumed and emissions generated in

the entire productive processes universe

to produce one unit of the material.

In the case of copper cathodes, the LCI covers the direct processes, from extracting the ore to its final refinement (see “copper processes” figure on page 14).

In its final stage, the methodological assumptions, scope, and results of the LCI were reviewed by a committee of independent experts, and their conclusions and recommendations were incorporated into the study.

![]()

Since 2010, we have registered our main

commercial products under the registration,

evaluation and authorization

of chemical substances system of the

European Union (REACH).

![]()

(2.10)

Awards received in the reporting period.

The Massachusetts Institute of Technology

(MIT) awarded Codelco with the

“Leadership in Innovation 2011 “ award

for the “Codelco Digital” technological

innovation project.”