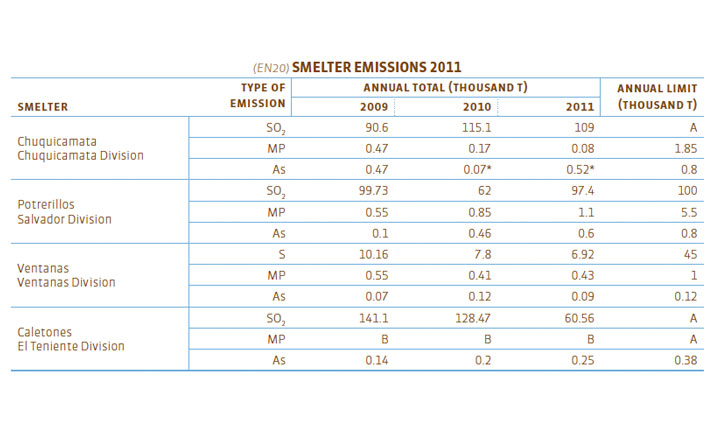

Smelter emissions

We care about controlling air emissions, and reducing the risk of polluting the atmosphere along with its potential impacts on the population, water, soil, and biodiversity.

At Codelco, we have four copper concentrate smelters, which generate, mainly, sulfur dioxide emissions (SO2), arsenic (As), and particulate matter (PM). These emissions are measured at the chimney output point for PM, and by balance in the case of As and SO2, in order to monitor that they are within the allowed ranges. We emphasize that all our smelters comply with annual legal emission limits.

A - Compliance with air quality regulations measured in contaminant concentration, where both Chuquicamata as Caletones comply.

B - In 2003 the Caletones Smelter stopped measuring these emissions, but continued to comply with the quality regulations for particulate matter.

* - According to the amendments to the S.D. 165/MINSAL/08, implemented in 2010, variations in the methodology for estimating arsenic emissions are included.

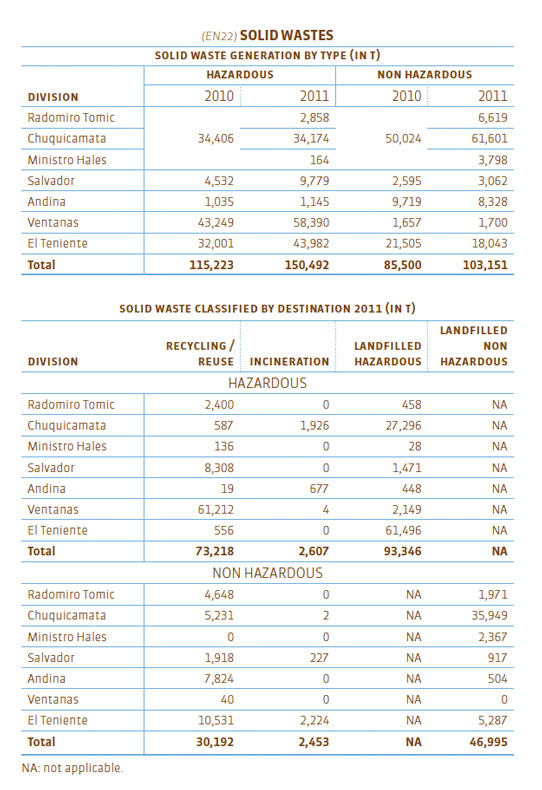

Industrial waste

In mining, the generation of solid waste and its proper management is important in environmental matters, not only because of the nature of these (which can be hazardous or non hazardous), but because of the large volumes generated. Having suitable conditions for its final disposal is a challenge for companies in our area. Therefore, our management focuses on the reuse and recycling, and controlling the risks associated with the handling and disposal of hazardous waste.

Since 2011 we have a Corporate Guideline on Solid Waste Management, which establishes the guidelines and actions, for the Corporation as well as for external companies who manage its wastes, regarding waste minimization.

![]()

(EN24)

Weight of transported, imported, exported, or treated waste deemed hazardous under

the terms of the Basel Convention Annex I, II, III and VIII, and percentage oftransported

waste shipped internationally.

It is important to

highlight that all waste

generated is landfilled

(both hazardous and non

hazardous waste) or disposed

of through authorized

waste management

companies, which in the

case of hazardous waste

is recorded by the Reporting

and of Hazardous

Waste System (SIDREP)

of the Ministry of Health.

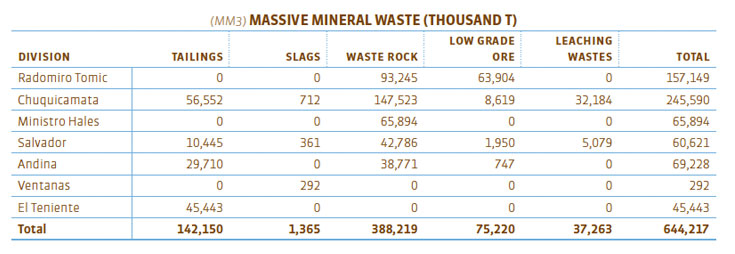

MASSIVE MINERAL WASTE

The challenge in managing massive mineral waste is finding innovative and creative solutions to encourage reuse and recycling, since they are characterized by its large volume and low risk to human health, if it is properly managed.

![]()

Slag Recycling

In order to become more efficient in our

productive process, during 2011 the

Chuquicamata, Salvador and El Teniente

Divisions reprocessed an important part

of their slag, which decreased waste generation

for this waste. In 2011, the total

amount of reprocessed slag reached 779

thousand tons.