Codelco is developing the largest investment plan in company history to continue transforming its extensive reserves into wealth for Chile. The plan includes the execution of some of the world’s biggest growth projects which will consolidate Codelco’s leadership in the industry. Key structural projects are Ministro Hales, Teniente New Mine Level and Chuquicamata Underground mine early works, initiatives that began construction in 2011.

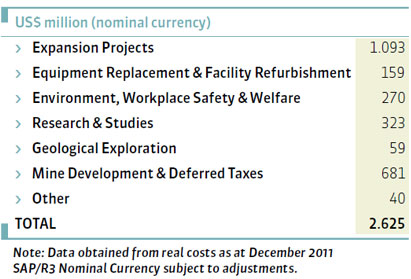

In 2011, Codelco invested US$ 2.625 billion in its portfolio of projects. It is the largest investment in the Company’s history and it reflects the intensive investment plan started during the year. This includes developing new mining projects to compensate the impact of declining ore grades at many of its existing operations, add new production and incorporate work practices that ensure Codelco’s medium and long-term competitiveness.

The Company’s structural projects are developments to extend continuity of mining operations at Codelco divisions and add long-term production. The following growth projects are under construction or in an advanced engineering phase:

- Chuquicamata Underground Mine

(early works) - Radomiro Tomic Sulphide Mine - Phase II

(prefeasibility study in final stage) - Mina Ministro Hales (in construction)

- Expansión Andina 244

(advanced feasibility study) - El Teniente New Mine Level

(under construction)

As part of the 2011 project portfolio and in order to maintain and develop its long-term competitiveness, investments were made at existing operations, particularly to renovate mining equipment and facilities, including relevant technology enhancements. Furthermore, an important technological innovation and research portfolio was implemented.

2011 INVESTMENTS

In 2011 Codelco conducted several pre-investment studies and projects totalling US$ 2.625 billion, described below:

Chuquicamata Division

Chuquicamata Underground Mine Structural Project

At the end of October the project early works were authorised, i.e., construction of the access tunnel for workers and material transport, air extraction shafts, air down-cast shafts for ventilation and surface infrastructure.

These early works require a US$ 875 million investment during the first 24 months. In line with the plan, the project feasibility study is also in progress and will be completed during the first six months of 2013.

Other Projects

During 2011, we continued to delineate the exploration resources at the Quetena deposit and the engineering studies to start extracting these leachable minerals by 2015. This plan will give continuity to copper production at the solution treatment plants, through solvent extraction and electrowinning (SX/ EW), at Chuquicamata Division. For this purpose, the current estimated mineral feed rate to the existing plant is 30,000 tonnes per day; and leaching low-grade oxide ore through heap leaching, at 60,000 tonnes of ore per day. The total estimated movement of mine material will be approximately 200,000 tonnes per day.

In 2011 studies were commenced on the division’s sulphide production line, these were required to ensure the continuity of operations and the output rates of the concentrator plant. While at the smelter, a study was started to enhance operations by stopping El Teniente Convertors and increasing fusion in the flash furnace to approximately 1,400,000 tonnes; fusion of concentrates from Chuquicamata Division mixed with calcine that will be produced at the new Ministro Hales Division. This new operating scheme will streamline operations (drying, fusion, slag cleaning, conversion and acid plants), increase work productivity and substantially reduce operating costs. This new operating model is scheduled for 2015.

At the end of 2011, the Talabre Dam project to raise its walls commenced, which will mean an extra 5 metres (raise the current 2,485 metres above sea level to 2,490 metres). This will increase tailings storage capacity, extending its operation life until 2016. The walls are primarily built with waste rock from Chuquicamata mine.

As of 2016, the Talabre dam will also store the tailings from the Ministro Hales mine and the sulphide ore from Radomiro Tomic mine. Therefore, studies were started on extending operation of the dam subsequent to 2016.

Radomiro Tomic Division

Sulphide Mine Structural Project Radomiro Tomic - Phase II

The Ministro Hales deposit (originally Mansa Mina) has approximately 1.3 billion tonnes of mineral resources, at an average grade of 0.96% copper. Once in operation, the open-pit mine will extract 289 million tonnes of ore to produce, over 15 years, an average of 170,000 tonnes of fine copper and 300 tonnes of silver per annum.

The project is in execution and includes the mine opening, the construction of a concentrator plant (primary crushing, grinding and flotation) that will process 50,000 tonnes per day and a roasting plant, in addition to other works.

Other Projects

During this period, the Electrolyte Cell Aeration Project was built and commissioned in order to significantly increase the number of cathodes in total production. The project also means more current and copper disposition efficiency.

Equipment procurement and construction work were well advanced in order to leave the primary leaching tailings dump fully operational.

At the same time, the engineering phase was completed and permits were obtained to extend tailings disposition until 2018, by building a new dump northeast of the existing disposition area. This area will have capacity for 300 million tonnes of tailings over a period of five years. It will also have capacity for secondary leaching that will produce approximately 150,000 tonnes of fine copper during the period 2013-2018.

Construction work also continued on the Low-Grade Oxides Leaching project; this project processes the large amount of oxides produced in the mineral extraction process.

Ministro Hales Division

Ministro Hales Mine Structural Project.

The Ministro Hales deposit (originally Mansa Mina) has approximately 1.3 billion tonnes of mineral resources, at an average grade of 0.96% copper. Once in operation, the open-pit mine will extract 289 million tonnes of ore to produce, over 15 years, an average of 170,000 tonnes of fine copper and 300 tonnes of silver per annum.

The project is currently in progress and includes the mine opening, the construction of a concentrator plant (primary crushing, grinding and flotation) that will process 50,000 tonnes per day and a roasting plant, in addition to other works.

Other Projects

Studies were conducted and completed for treating leachable mineral resources extracted during prestripping. The copper solution from leaching is sent to the solvent extraction/electrowinning plant at Chuquicamata Division.

Leaching facility construction is scheduled to commence during the second half of 2012. The Leachable Resource Extraction project will contribute an annual average output of more than 23,000 tonnes of fine copper over the 2013-2015 period.

Salvador Division

San Antonio Oxide Project

The project feasibility study started in July focused on mining and processing the remaining resources at the old Potrerillos Mine (formerly Mina Vieja), that will help to extend the life of the mine operation at Salvador Division and add copper output. The development includes the construction of an ore crushing plant, which will be transported on conveyors to the moist area, formed by leaching, solvent extraction and electrowinning plants, located 9 kilometres away in the Potrerillos area.

The project has a very demanding programme that is scheduled to complete basic engineering in 2012 and start cathode production by 2015.

During the year, new metallurgical studies were conducted, increasing the estimated throughput capacity, from 30,000 to 60,000 tonnes of fines copper per year. Currently the company is carrying out studies related to this new capacity.

Other Projects

During 2011 analyses and studies were conducted to extend operations and reinforce the competitiveness of Salvador Division. These extension projects aim to solve the current deficit conditions as a result of the decision to close the mine.

Likewise, focus was on restoring productivity standards and expanding capacity with projects such as the Concentrator Capacity Expansion project that will install more powerful engines at certain mills, enhancing capacity and solving spare parts problems which are required for engines in this section. This development aims to increase fine copper concentrate production.

At the end of the year, construction of the Cleaning System for El Teniente Convertor Slag project commenced at the Potrerillos industrial facilities. Hence, the existing process to recover copper from slag in the electric furnace will be replaced by a slag treatment and flotation process that will obtain high grade copper concentrate. The treatment capacity of the existing plant design is 1,700 tonnes of slag per day, which will have a positive impact as it will increase the smelter metallurgical recovery by 97.4%.

Ventanas Division

Key projects implemented in 2011 focused on managing gases and particulate matter and on improvements in innovation to enhance productivity, reduce costs and reduce risks to people.

These projects increase particulate matter capture in the electric furnace, mitigate particulate matter emissions in concentrate and raw material management and transport processes to the smelter. They also reduce particular matter in the management and disposal processes of the dust emissions from these processes.

In relations to gas treatment and capture, the sulphuric acid plant improvement was started together with the need to implement a system to capture and treat fugitive gases at the bleeder points of smelted material and tail gas fom the acid plant. Likewise, studies were implemented to mechanise the cold load feed to Pierce Smith Converter No. 2 to prevent fugitive gas emissions.

Andina Division

Andina Expansion 244 Structural Project

The project expands the nominal treatment capacity to 150,000 tonnes of ore per day, up from 94,000 to 244,000 tonnes per day. For this purpose, it considers a major expansion of mine operations, a primary crushing process on the mine site, the construction of new concentrator facilities and the development of infrastructure - for example, mineral transport systems through tunnels, hydraulic transport of concentrates, filter plant, power line, water supply and propulsion - consistent with a large-scale operation as projected. This will increase annual throughput capacity at Andina to more than 600,000 tonnes of fine copper.

In late 2011, a series of access road improvement works and energy supply reinforcements were identified and that need to be implemented during 2012 and 2013.

Other Projects

The construction of Río Blanco water diversion tunnel was completed that will prevent fresh water contact with waste rock dumps. Work was also started on North Tailings Deposit Drainage Water Treatment project, and its feasibility study will soon be completed.

As for short-term continuity of operations, the following projects were completed: Water Standardization – Stage I; Underground Mine Air Injection System Modification and work to ensure operation of the Ovejería Tailings Dam.

Studies and early works were continued in order to provide this open-pit mine in the mountains a new system to transfer ore to the concentrator plant.

El Teniente Division

New Mine Level Structural Project

This development will extend El Teniente mine to a deeper section of the mine, adding nearly 2 million square metres, with reserves totalling 2.02 billion tonnes and an average grade of 0.86% copper and 220 ppm of molybdenum. The project will extend the useful life of the mine by 50 years as of 2017 and, therefore prevent mine closure.

At the beginning of 2011, the feasibility stage was completed and in March its Environmental Impact Assessment was approved. In July the funds for the investment implementation stage were authorised and therefore work was started. While in August the construction contract for the main tunnels was awarded.

The construction of the project early works is in progress, such as the platforms in the area known as Confluencia and the emergency exit ramp; both will be completed in mid-2012.

Other Projects

In 2011, Rajo Sur mine project was under construction; this Project includes opening an open-pit mine in the mountains, which will contribute an average of 15,000 tonnes of mineral per day. At the end of 2012, the Sewell concentrator facilities will be used for ore treatment.

Furthermore, the Diablo Regimiento - Phase IV project commenced; it will contribute 10,000 tonnes per day to El Teniente mine production and it will start operations at the beginning of 2014. The mineral from the new area of the underground mine will help to replace depleted mine areas. All the Diablo Regimiento section, and its different phases, will contribute 28,000 tonnes of mineral per day in 2014.

In 2011, the fifth stage of the Carén dam wall raising was completed, extending its useful life until 2015; studies will be implemented in order to commence early works for the sixth stage in 2012.

Gabriela Mistral Mine

In 2011 and in order to give continuity to the project to recover copper from tailings resulting from Gabriela Mistral mine ore leaching process, early works continued on the drainage system to capture copper-containing solutions.

Additionally, the feasibility study was completed and the project data was submitted for authorisation at the end of the year. The project will be implemented during the first half of 2012 and its will start operations at the end of the year. Overall, it will contribute 50,000 tonnes of fine copper recovered from tailings over a period of five years.

Enhancements to crushers and other minor equipment adjustments at the crushing plant were started in order to increase productivity of facilities and eliminate certain restrictions in the plants.